Vita Craft, Kansas City’s Cookware Secret, Marks 78 Years in Business

By Robin Mather

The seed of an idea hatched over a round of golf in 1939 has grown into a cookware manufacturing business that flourishes today in Kansas City, Kansas.

Glen Slough, Eddie Durwachter and Win Cook, all direct cookware salesmen, weren’t happy with their company’s opportunities. The trio decided to manufacture a superior product with better design, and Vita Craft was born. The budding company flourished with direct sales only, but in 1943 the company closed briefly because the war effort diverted the materials need to manufacture the cookware. When the War Production Board granted Vita Craft a license to resume making its products in 1945, the company was back in business and hasn’t looked back since.

Glen Slough, Eddie Durwachter and Win Cook, all direct cookware salesmen, weren’t happy with their company’s opportunities. The trio decided to manufacture a superior product with better design, and Vita Craft was born. The budding company flourished with direct sales only, but in 1943 the company closed briefly because the war effort diverted the materials need to manufacture the cookware. When the War Production Board granted Vita Craft a license to resume making its products in 1945, the company was back in business and hasn’t looked back since.

From its beginnings as a direct-sale company, Vita Craft is now moving into the retail market with its own line. Cookware retailers who are interested in its products will find Vita Craft at the International Home and Housewares Show.

Vita Craft has been pleasing customers for decades with its waterless, greaseless cooking systems. Its careful construction means food can cook quickly and easily with virtually no additional water or fats, cleanup is easy and the pots and pans can last a lifetime – or two.

In addition to its high-quality construction, one of Vita Craft’s chief selling points is its lifetime guarantee for consumers, and the company backs that 100 percent, says Gary Martin, Vita Craft’s President today. “I’ll still replace handles, no matter how old the pan is,” he says. “If you have a Vita Craft pan, I’ll take care of it. And if you have someone else’s pan, I’ll try to fix that, too.” The company also partners with a number of cooking schools, and gives those clients a three-year warranty, because they use the pans much harder than an ordinary home cook would do, he says.

In addition to its high-quality construction, one of Vita Craft’s chief selling points is its lifetime guarantee for consumers, and the company backs that 100 percent, says Gary Martin, Vita Craft’s President today. “I’ll still replace handles, no matter how old the pan is,” he says. “If you have a Vita Craft pan, I’ll take care of it. And if you have someone else’s pan, I’ll try to fix that, too.” The company also partners with a number of cooking schools, and gives those clients a three-year warranty, because they use the pans much harder than an ordinary home cook would do, he says.

“Home users take care of their cookware, because they see it as an asset,” he says. “Commercial users see it as a cost of doing business, and expect to replace it every couple of years.”

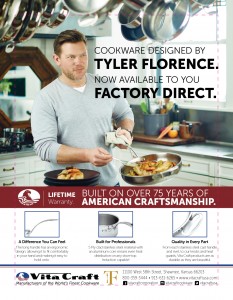

The company also does private-label manufacturing, including a special line for chef and Food Network star Tyler Florence. “Vita Craft was the first set of pots and pans that I learned to cook with when I was probably eight years old. No kidding, it’s the most durable, easy-to-use cookware I’ve ever had,” Florence says. “And I think they’re stunning.”

The company also does private-label manufacturing, including a special line for chef and Food Network star Tyler Florence. “Vita Craft was the first set of pots and pans that I learned to cook with when I was probably eight years old. No kidding, it’s the most durable, easy-to-use cookware I’ve ever had,” Florence says. “And I think they’re stunning.”

In his cookware line, long upswept handles offset the pans’ weight, making them easy to lift even when filled with food. The metal knobs and riveted handles lend the pans a contemporary appearance shared with Vita Craft’s commercial line. As for Vita Craft’s own line, Martin says, “we knew it required some redesign when we began to go into the commercial and retail business about six years ago.”

The changes are cosmetic, not structural. “We still make our pans with five plies: surgical stainless steel, and an aluminum core that goes all the way up the sides to the rim,” he says. “Our handles are phenolic resin,” – like Bakelite, he adds – “And not plastic, so they can take the oven’s heat – up to 400 degrees.”

But the oven-safe handles may be the least of the cookware’s features. The pots, pans and lid are dishwasher safe. Vita Craft’s pots and pans are designed to accommodate a self-storing lid. When food is heated in the pan, the lid creates a vapor seal that means the food inside can be cooked quickly and easily in its own juices. The vapor seal is created by heating the food over medium heat, then reducing the heat to low for the appropriate time. Users know the vapor seal has been created and it’s time to reduce the heat when the lid is hot to the touch and spins freely.

There’s another Vita Craft benefit that its users love: stack cooking. The company has designed its pans so that lids can be inverted and other pans can stack atop them. The five-ply construction conducts heat up the sides of the pan and transfers heat to the upper vessel. “We engineered 32 basic variations into the system,” boasts the company’s website.

Stack cooking means that a roast and vegetables can go in the bottom pan, additional vegetables can go into a pan that sits atop the bottom pan, and a cake can bake in a top pan resting on the middle pan. Using lower temperatures and just one burner means stack cooking energy savings, says the website.

With 70 percent of its sales in exports to Taiwan, Japan and South Korea, where it is consistently praised as the best cookware available, most of the company’s domestic sales come from a few remaining direct sales people, with a few in-home salespeople and some bridal business sales. Marmaru Imura is the CEO and major shareholder in Vita Craft. He’s based in Kobe, Japan, and also happens to have been the largest Vita Craft distributor. He learned about Vita Craft while he attended Harvard University. The story goes that he learned about Vita Craft from a family friend of the Rockefellers, whose chef would only use Vitacraft cookware. “Over in Japan, the cookware is in department stores – they would have a space inside the store staffed with their own people,” Martin says. Imura is responsible for making Vita Craft into a household name in Japan.

With 70 percent of its sales in exports to Taiwan, Japan and South Korea, where it is consistently praised as the best cookware available, most of the company’s domestic sales come from a few remaining direct sales people, with a few in-home salespeople and some bridal business sales. Marmaru Imura is the CEO and major shareholder in Vita Craft. He’s based in Kobe, Japan, and also happens to have been the largest Vita Craft distributor. He learned about Vita Craft while he attended Harvard University. The story goes that he learned about Vita Craft from a family friend of the Rockefellers, whose chef would only use Vitacraft cookware. “Over in Japan, the cookware is in department stores – they would have a space inside the store staffed with their own people,” Martin says. Imura is responsible for making Vita Craft into a household name in Japan.

Imura bought the company in 2002, and has said that his goal has been to make sure that Vita Craft remains a “made in the USA” product, according to the company’s website. Vita Craft makes its pots and pans in the 78,000-square foot plant where the company got its beginnings. Over the years, it has expanded, built on and converted buildings as it grew, but it still incorporates the company’s original footprint. With about 31 employees, all but one of them full-time, Gary says, the company’s now running two shifts. “We have been up to three shifts, but it’s a little bit seasonal,” Martin says. Several of the employees have been with the company for 30 years or more, and for some, Vita Craft has been their first and only job.

Since Martin joined Vita Craft in 1993, he’s been a hands-on boss, including interview potential employees. “They should have some mechanical aptitude, but the most important thing to me is that they should have some ethics.” As we tour the plant, employee after employee greets Martin, calling him by his first name and smiling at me. “I never could do the invisible boss thing,” he says. Again and again, Martin points out equipment that has been in use since the company began. “We’re still making cookware the same way as they were making it in the beginning,” he says.

“Vita Craft’s an old company, but we’re not old in thought. We evolve with the times. We’re a real brick-and-mortar store with real people who have real families. We work hard, and we go home dirty at the end of the day,” Martin says. There’s pride in his voice when he says that. Pride, and a great deal of love for the work he does.

You must be logged in to post a comment.